Counterbalanced stacker is an important equipment for handling and stacking goods. It can efficiently stack and carry goods in a small space. This article will introduce the principle, structure, working principle and application of counterbalanced stacker in the logistics industry in detail, and explore its importance in improving work efficiency and reducing labor intensity.

1. Principle of counterbalanced stacker

The counterbalanced stacker adopts the counterbalanced weight principle, which balances the weight of the goods between the body and the fork arm so that the vehicle can maintain balance during the stacking process. It usually consists of a body, a fork arm, a hydraulic system and an electric motor.

2. Structure of counterbalanced stacker

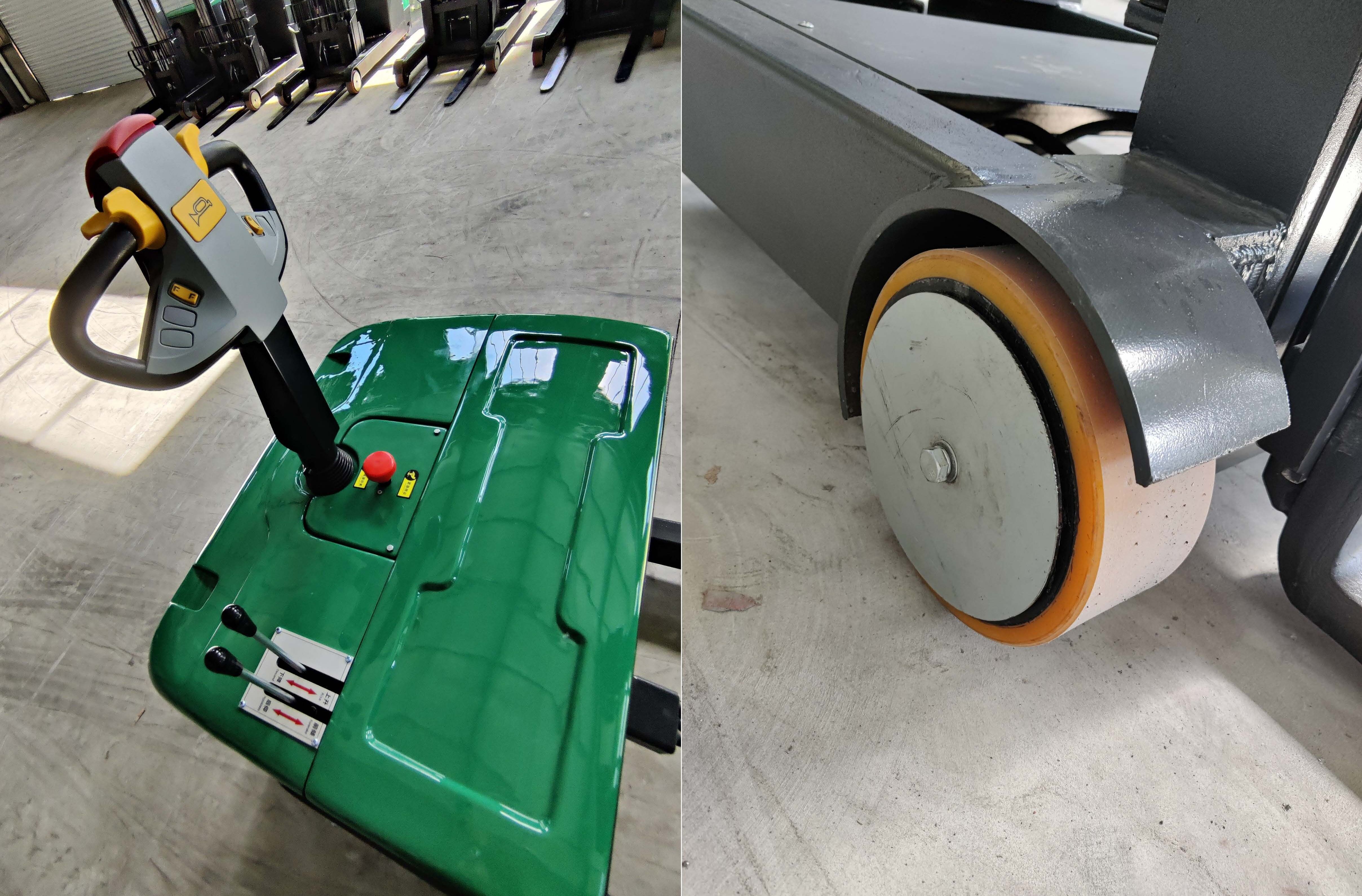

1. Body: The body of the counterbalanced stacker is usually made of steel and has sufficient strength and stability. The body is equipped with equipment such as a cab, a console and an operating lever to facilitate the operator to operate.

2. Fork arm: The fork arm is an important part of the counterbalanced stacker, which is used to handle and stack goods. The fork arm is usually made of steel and has sufficient strength and rigidity. The fork arm is equipped with a fork that can be raised and lowered as needed.

3. Hydraulic system: The hydraulic system is the power system of the counterbalanced stacker, which is used to control the lifting and lowering of the fork arm and the extension and retraction of the fork. The hydraulic system consists of a hydraulic pump, a hydraulic cylinder, and a hydraulic valve, etc., and the movement of the fork arm is achieved by controlling the flow of hydraulic oil.

4. Motor: The counterbalanced stacker usually uses an electric motor as a power source, which drives the movement of the hydraulic system and the vehicle through electric energy. The electric motor has the advantages of high efficiency, environmental protection and low noise, and is suitable for various working environments.

3. Working principle of counterbalanced stacker

The working principle of the counterbalanced stacker is to control the lifting and lowering of the fork arm and the extension and retraction of the fork through the hydraulic system to achieve the handling and stacking of goods. The operator controls the work of the hydraulic system through the buttons and levers on the console to make the fork on the fork arm lift and retract. By adjusting the height and angle of the fork arm, the goods can be accurately stacked at the designated location.

4. Application of counterbalanced stackers in the logistics industry

Counterbalanced stackers are widely used in the logistics industry. They can be used in places such as warehouses, docks, factories and logistics centers for handling and stacking various goods. Counterbalanced stackers have the following advantages:

1. Improve work efficiency: Counterbalanced stackers are able to stack and carry goods in a small space, which improves work efficiency. They can quickly and accurately move goods from one location to another, saving time and labor costs.

2. Reduce labor intensity: Counterbalanced stackers can replace manual handling and stacking work, reducing labor intensity. Operators only need to operate through buttons and levers on the console, without having to carry the goods in person, reducing physical burden.

3. Improve safety: Counterbalanced stackers have a stable structure and precise control system, which can ensure the safety of goods during stacking. They can accurately stack goods in designated locations, avoiding tilting and falling of goods.

4. Strong adaptability: Counterbalanced stackers can adapt to various working environments and cargo types. They can operate flexibly in a small space and are suitable for cargo of different sizes and weights.

Summary:

Counterbalanced stackers are an important equipment used for handling and stacking goods. They use the counterweight principle and control the lifting and lowering of the fork arm and the extension and retraction of the fork through the hydraulic system to achieve the handling and stacking of goods. Counterweight stackers have the advantages of improving work efficiency, reducing labor intensity, improving safety and strong adaptability, and play an important role in the logistics industry. In the increasingly busy logistics environment, the role of counterweight stackers is indispensable and has great significance for improving work efficiency and reducing labor intensity.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

HY

HY

AZ

AZ

KA

KA

UZ

UZ